The Machining Research Group was founded in the 1980s following the move of David Aspinwall from the Department of Engineering Production to Mechanical Engineering and subsequent interaction with Dr. Mike Wise from Metallurgy and Materials in the then newly formed Interdisciplinary Research Centre (IRC) in Materials for High Performance Applications funded by the EPSRC. A further key member – Dr. Richard Dewes joined in the early 1990’s. The Group has an international reputation as a centre of excellence for conventional and non-conventional machinability research involving a wide range of advanced aerospace alloys and workpiece materials.

Currently led by Dr. Leung Soo (since 2011), the Group has been further strengthened by the appointment of Dr. Richard Hood (February 2013) to a lectureship in advanced manufacturing technology, who prior to his current role was the Rolls-Royce Research Fellow in machining for 5 years. Work in the MRG has been funded by a succession of major grants from the EPSRC, EU, TSB and the Government regional development agency (AWM), together with a significant number of industrial contracts from major OEM and first tier supplier companies such as Rolls-Royce, Airbus, GKN Aerospace, Doncasters, Corus, Seco Tools, Element Six, Mitsubishi Carbide, GF Agie-Charmilles, Mapal, Saint-Gobain Abrasives, Matsuura, Unimerco, Erodex, Hardinge, Delcam, Winbro Group and Iscar.

Collaboration with the UK’s major trade bodies – the Gauge and Toolmakers Association (GTMA) and the Manufacturing Technologies Association (MTA) has provided the Group with an extensive network of industrial organisations through which technology transfer events have been run. Additionally, the involvement of key members of the Group in the prestigious International Academy for Production Engineering (CIRP) allows interaction and participation in leading worldwide research initiatives. The Group has successfully graduated some 30 PhD’s researchers since 1994, specifically in machinability related topics and published some 300 papers. The research activities can be broadly categorised (but not limited to) into 3 main themes/strands as described below:

Machinability of advanced materials:

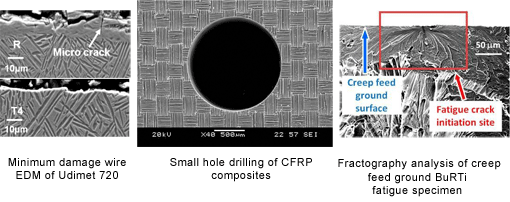

The principal focus here is in understanding and characterisation of the influence of material removal processes on workpiece surface integrity (e.g. microhardness, microstructure alterations, residual stress, surface roughness and fatigue performance) as well as subsequent part functionality. Statistical analysis techniques are employed to identify significant process variables and optimum operating windows (preferred tooling / tool wear evaluation) with respect to defined response parameters.

The research encompasses a wide range of conventional (i.e. turning, high speed milling, grinding, drilling etc.) and non-traditional cutting operations, in particular various configurations of electrical discharge machining (EDM) based processes (e.g. die sinking, wire cutting, ED texturing and surface alloying etc.), ultrasonic machining (USM) and electrochemical machining (ECM).

This has also recently translated to evaluation of microscale mechanical machining involving micro high speed milling (with end mills down to 0.1 mm in diameter) as well as micro wire and die-sink EDM utilising wires / electrodes down to 0.02 mm diameter. Workpiece materials evaluated are typically classified as ‘difficult to cut’ including advanced titanium alloys (Ti-6Al-4V, Ti-6Al-2Sn-4Zr-6Mo, gamma-TiAl, burn resistant titanium) and nickel based superalloys (Nimonic 80, Inconel 718, Udimet 720, Haynes 282, RR 1000), hardened steels (AISI H13, D2, D3, M2 etc.), aluminium alloys including hypereutectic (17% Si) compositions and MMC’s, zirconium alloys and more recently carbon fibre reinforced plastic (CFRP) composites.

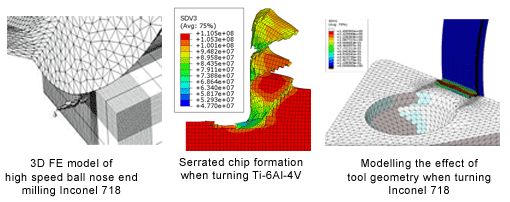

Process modelling and simulation of metal cutting operations

This strand of research concentrates on developing numerical and computational models / simulations (primarily based on finite element methods) of machining processes in order to predict key response measures including cutting forces, temperatures, chip morphology, residual stresses and more recently workpiece surface integrity parameters.

The aim is to provide greater insight into the mechanisms affecting the chip formation process and potentially reduce the volume of experimental testing required for manufacturing validation of new component designs / materials. Both 2D and 3D simulations have been developed using a variety of commercial FE packages including ABAQUS and DEFORM.

A further activity is the formulation of new constitutive material relationships to better describe workpiece flow stress behaviour under machining conditions, which is supported by data from high strain rate / temperature material property testing. Researchers have access to a Gleeble thermo-mechanical simulator while a new Split-Hopkinson Pressure Bar (SHPB) system is currently being commissioned.

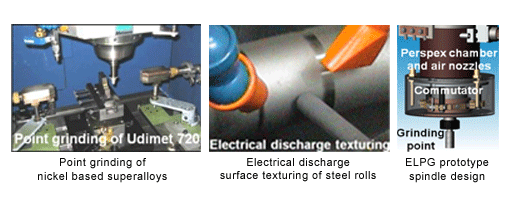

Innovative machining process development:

The research carried out in this area concentrates on the development of new or alternative process configurations in order to achieve greater productivity coupled with improved machinability / surface integrity or specific surface characteristics / functionality.

This includes hybrid operations where two or more processes are employed simultaneously on a single platform, such as electrolytic point grinding (ELPG), ultrasonic assisted creep feed grinding (UACFG) and ultrasonic assisted WEDM.

Extensive research has been carried out involving EDM including electrical discharge texturing / surface alloying, in-process electrical discharge dressing (IEDD) and minimum damage WEDM together with innovations such as point grinding of fir tree root forms for turbine disc applications.

Research facilities:

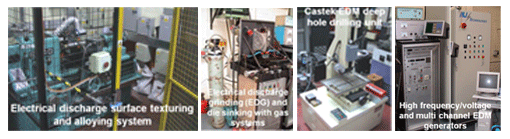

The Group has built one of the most comprehensive research laboratories in any UK academic institution with an equipment base of approximately £2.5M. This comprises industrial scale high speed machining centres with linear motor capability and spindle speeds up to 120,000rpm, several wire/die-sink EDM units, a flexible grinding centre (courtesy of Winbro Group) and bespoke hybrid processing systems.

In addition to the commercial machine tools detailed above, the Group has a range of advanced EDM related technologies including systems for texturing and surface alloying, electrical discharge grinding, deep hole drilling, water deionisation together with multiple pulse generators offering open circuit voltage up to 600V with high frequency capability.

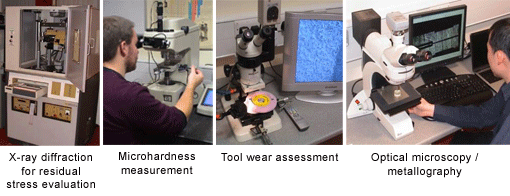

Additionally, the Group has an extensive suite of complementary analysis equipment encompassing video tool wear systems, a range of Kistler piezoelectric platforms / rotating dynamometers for force measurement, infrared cameras for temperature measurement as well as access to leading edge surface / dimensional metrology equipment and facilities for in-depth workpiece surface integrity analysis. This includes optical and scanning electron microscopy (SEM), sample preparation and metallography, coordinate measuring machine (CMM), microhardness evaluation, X-ray residual stress and fatigue equipment.

Routes for industrial and academic collaboration

The Group welcomes contact from industrial organisations who wish to discuss potential project partnerships or develop grant proposals to secure EPSRC, TSB, EU and RAEng (or similar Government funding) research funding together with direct industrial contracts, KTP programmes and PhD studentships. We are also interested in hearing from international academic colleagues who would like the opportunity to work with us as visiting researchers (typically 9 – 12 months duration) on projects of mutual interest.

Contacts

Dr. Leung Soo

Email: s.l.soo@bham.ac.uk

Dr. Richard Hood

Email: r.hood@bham.ac.uk