3-D printing is a promising technique to produce RF and microwave passive circuits. Compared with conventional machining techniques, 3-D printing enables manufacturing complex structures with great geometrical complexity and/or printing the devices into a standalone part without the need of further assembly. Another great advantage of 3-D printing is the significant weight reduction, when the device is printed from polymer and metal coated.

The EDT group have demonstrated a range of novel 3-D printed passive circuits. These circuits cover a wide frequency range, from 0.5GHz to 100GHz, and include a 0.5 GHz helical resonator filter, a 3 GHz combline filter, two 10 GHz waveguide filters based on spherical resonators, a 15 GHz filtering Butler matrix, a 30 GHz OMT, and two 90 GHz waveguide filters. Among them, the 90 GHz filters represent the highest frequency 3D printed filters reported in open literature to date; these filters have been made in both metal and metal coated plastic.

Most of the devices studied in the EDT are based on lightweight polymers, which are capable of handling high temperature when ceramic filled resin is used. 3D metal printing is also utilised to produce several designs including the W-band filter. All of the circuits are optimised for 3D printing, so that enhanced microwave performance and/or considerable weight reduction can be achieved. This cluster of work demonstrates the great potential of using 3D printing for microwave applications.

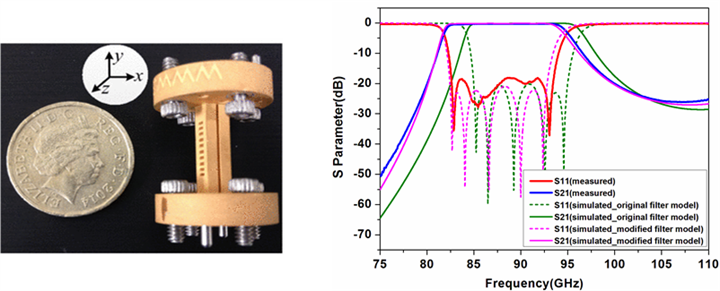

As an example of the work we will describe the W-band filters. A polymer filter was made in collaboration with Swissto12 Ltd, as shown in figure 1. This is a fifth-order Chebyshev filter with a center frequency of 90 GHz and an equal ripple bandwidth of 10 GHz. The passband return loss is designed to be 20 dB. The filter is printed from photosensitive resin using stereolithography (SLA) process and is subsequently coated with 10 μm thick copper all around. The filter is designed to have slots on both broadside and narrow side walls. This reduces the weight even further and facilitates the metal plating process allowing easy flowing of solution, while at the same time not having the penalty of degraded insertion loss. Measurement responses show visible frequency shift and this is attributed to fabrication inaccuracies. The modified filter model taking account of these inaccuracies is simulated in CST and the results agree well with measurements. The deviation in dimensions is due to enlargement in post-curing step of the printing process, and could be corrected by remaking the filter with modified dimensions.

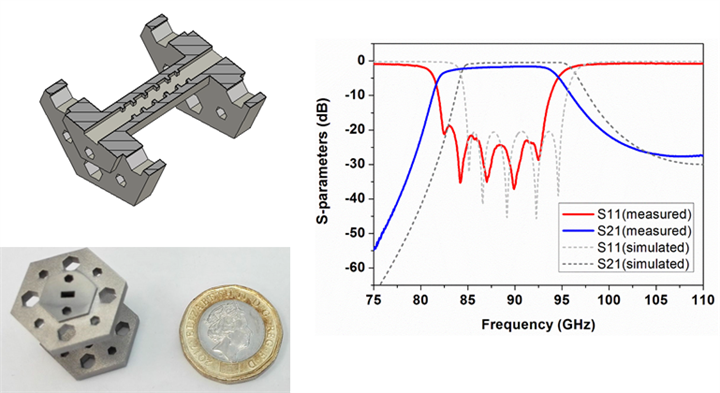

An alternative to SLA printing is 3D metal printing using selective laser sintering (SLS) process. SLS allows all metal devices to be printed and is of particular interest to devices demanding high thermal stability. In collaboration with 3DMicroPrint and University of Hong Kong, a W-band filter is printed from steel powder, as shown in figure 2. This filter is designed to have the same specifications as the plastic one shown in figure 1. Measurement results of the metal filter agree well with simulations.

There has been no tuning to either of the two filters. These two filters represent the highest frequency 3D printed waveguide filters demonstrated to date. The manufacturing process will improve over time and we expect 3D printed filters moving into the sub-terahertz region soon.

Figure 1: (a) Photograph of the 3-D printed W-band filter. (b) Measurement and simulation results of the filter. Passband insertion loss is measured as 0.4 dB, compared with simulated 0.15 dB. The filter is made by Swissto12 (Switzerland).

Figure 1: (a) Photograph of the 3-D printed W-band filter. (b) Measurement and simulation results of the filter. Passband insertion loss is measured as 0.4 dB, compared with simulated 0.15 dB. The filter is made by Swissto12 (Switzerland).

Figure 2: (a) Illustration diagram and photograph of the 3-D printed W-band steel filter. (b) Measurement and simulation results of the filter. Measured average passband insertion loss is around 2 dB, which is 1.5 dB higher than simulation. The filter is made by 3DMicroPrint (Germany), and the post-processing is done at University of Hong Kong.

Figure 2: (a) Illustration diagram and photograph of the 3-D printed W-band steel filter. (b) Measurement and simulation results of the filter. Measured average passband insertion loss is around 2 dB, which is 1.5 dB higher than simulation. The filter is made by 3DMicroPrint (Germany), and the post-processing is done at University of Hong Kong.