We are developing high-gain and high-efficiency THz periodic metasurfaces and antennas based on novel cost-efficient micromachining of metalized polymer (SU8). Removing dielectric substrates and the creating air cavities helps deliver significant improvements to antenna efficiency and gain.

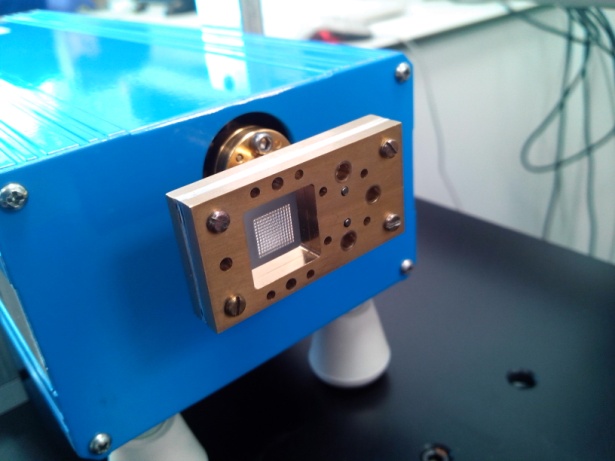

We have developed a A 300GHz antenna prototype fabricated using multi-layer, metal coated, SU8 substrate, incorporating a waveguide H-bend. All layers are constructed from one SU8 wafer with a thickness of 0.432mm. The complete antenna structure comprises of six layers and two thick brass plates placed on the top and the bottom of the antenna in order to clamp the layers together and provide a way to connect the waveguide flange. We incorporated a waveguide bend in order to facilitate the efficient interconnection of the antenna and the measurement system.

Fabricated 300GHz antenna installed on the test equipment

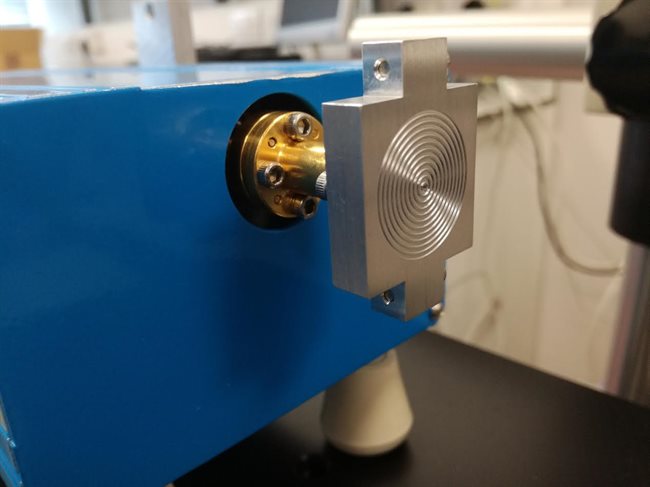

We also study the use of corrugated ground planes for the development of high gain antennas in the mm-wave and low-THz spectrum. Our research focuses on the mathematical modelling of the dispersion characteristics and the leaky-wave analysis of these antennas; the design of terahertz antennas with new geometrical patterns; and the use of frequency selective surface type structures for performance enhancement.

Corrugated ground plane antenna (Bull’s Eye) operating at 300 GHz