AMPLab facilities

Concept laser M2 cusing system: selective laser melting (SLM)

- Argon atmosphere for the processing of reactive powder systems

- Net shape manufacture of fully dense components

- Build envelope 250 x 250 x 280mm

- Layer thickness 20 – 50µm

- Production speed 2 – 20cm3/hr (depending on material)

- Fiber laser system (400W, cw)

- Maximum scanning speed 7m/s

- Focus diameter 70 – 200µm

SLM solutons SLM500 HL: multi-laser large bed SLM

- 4 Lasers (2x 1kW + 2x400W) (cw)

- Build envelope 500 x 280 x 325 mm

- Layer thickness 20 – 200 μm

- Production speed 2 – 20 cm3/h

- Scanning speed 15 m/s

- Focus diameter 80 – 150/700 μm

- Parameters for Al, Ti, Ni, & Fe

- Heated substrate (200˚C)

- Powder spreading module

Trumpf direct laser fabrication (DLF) system

- Machine Limit – 1.5×1.0x3.0m

- Laser system Disk laser 4kW (Continuous and Pulsed Wave)

- Laser spot size: 0.4 – 6mm

- 5-axis CNC control movement

- Can be operated in powder and wire-fed deposition modes

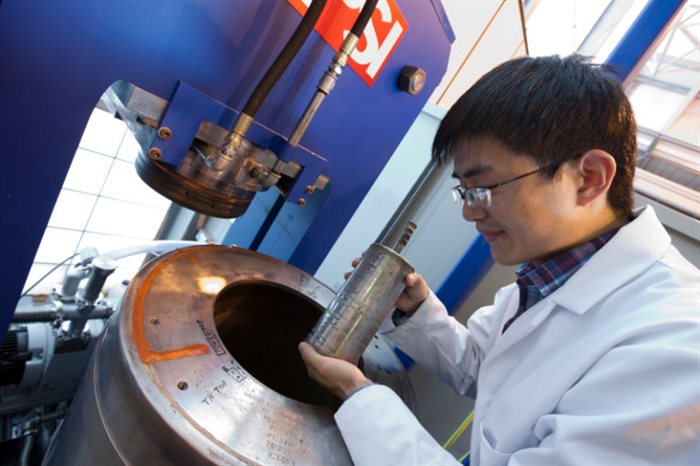

EPSI hot isostatic press (HIP)

- Maximum pressure: 200MPa

- Maximum temperature: 1450°C

- Vessel size: Ø120mm x 300mm

HP 3D printer (fused deposition modelling)

Formlab stereolithography system

Vacuum and argon heat treatment furnaces

Wire electric discharge machining

3D scanner