This page shows some micrographs taken from Group research projects obtained using SEM and TEM techniques.

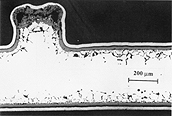

Figure 1

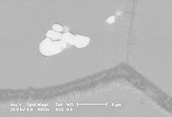

Figure 2

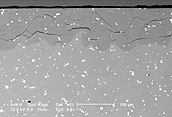

Figure 3

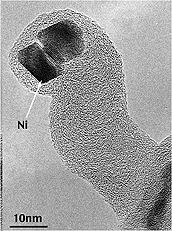

Figure 4

Fig 1 Alloy failure at a rib extremity in Fe20Cr25Ni steel after 7000 hours at 950ºC. The dark crack-like regions are silica intrusions along the grain boundaries.

Fig.2 Close-up of the internal oxidation zone in standard-grade Sm2(Co,Fe,Zr,Cu)17 magnetic alloy oxidised for 200 hours at 500ºC, showing a samarium-oxide particle and a vein of copper-rich precipitate.

Fig.3 Internal oxidation zone in standard-grade Sm2(Co,Fe,Zr,Cu)17 magnetic alloy oxidised for 200 hours at 500ºC. The black layer is the external iron-oxide scale, the white specks are samarium-oxide particles (created during magnet production) and the dark crack-like regions are copper-rich precipitates.

Fig. 4 High resolution TEM micrograph of a carbon filament. The dark particles at the tip are shown to have lattice parameters consistent with metallic Ni viewed along a fcc (110) axis.