Multi-Criteria Decision Making in Manufacturing Supply Chain Management

[collaboration with GFM S.r.l (Italy), the MTC (UK)]

Holonic Manufacturing System Modelling

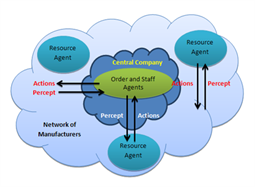

Holonic manufacturing system has been researched and used for real problem solving in situations where performance optimisation is essential amidst the perturbation in the manufacturing environment. This approach was tested on various use cases such as labour recruitment and capacity demand management in the context of labour intensive industries, cost-effective use of existing machines and new machines on the shop floor, and the coordination of distributed manufacturing to optimise the overall throughput lead time, cost and quality.

Decision Making in Supply Chain Management

The supplier (vendor) selection has achieved a high level of importance in a modern supply chain infrastructure. The complexity of this problem is due to both quantitative and qualitative features, which may exhibit conflicting behaviours and uncertainty. Object-oriented programming and database design have been used to establish research models of manufacturing systems. The modelling approach is very flexible for developing distributed decision-making algorithms in manufacturing systems.

Increasing Resilience of Manufacturing Networks to Production Disturbances

[collaboration with GFM S.r.l (Italy), and the MTC (UK)]

Holonic manufacturing system approach (HMS) is used to model manufacturing systems as self-similar building blocks arranged in a hierarchical and heterarchical structure. Our research group has extensive experience in testing various use cases such as workforce allocation and capacity demand management in the context of labour intensive industries, cost-effective use of existing machines and new machines on the shop floor, and the coordination of distributed manufacturing to optimise the overall throughput lead time, cost and quality. The high quality HMS-based solutions have outperformed many of the conventional practices of the use cases for their respective objectives. In the light of the above, the capabilities to develop and run models of manufacturing systems on the shop-floor and at manufacturing network level and to generate insight into new logics of planning and scheduling in those domains are enhanced by the HMS approach. The rapid development in multi-agent systems will eventually enable the implementation of distributed algorithms, system architectures and interaction protocols developed in our work into live manufacturing execution systems (MES).

Contact

Dr. Mozafar Saadat

E-mail: m.saadat@bham.ac.uk