We have a solid materials research base, with many years of experience in superconducting, ferroelectric, dielectric and meta-materials. We combine research into manufacturing technologies with basic science and characterisation of materials. We regularly collaborate with industrial end users to demonstrate the applications of our research.

Our research focus is strongly informed by the requirements of the communications and sensing industries. This helps determine the choice of materials and technology we investigate. Our main areas of research are summarised below.

Terahertz components

Terahertz radiation is electromagnetic radiation with a frequency above the radio frequency (RF) and microwave region and extending towards the optical range. It is an area of the electromagnetic spectrum which is under-used at the moment due to the difficulties in producing practical components and systems. However, it is widely understood that terahertz will be important in the future for many applications. Our research focuss on the design and testing of terahertz circuits.

Terahertz radiation has five primary properties for applications:

- It is able to pass through dielectrics such as paper, plastic, cloth, wood, ceramics and silicon, which are also common packing materials

- Metals are highly reflective in the terahertz region

- Many chemical and biological agents have unique spectral fingerprints in the terahertz frequency region

- Compared with X-rays, terahertz radiations do not present health hazard to people being scanned or to people operating the scanned systems

- Large bandwidths are available for communications systems.

Due to these advantages, there is an increasing interest in terahertz frequencies and many companies and universities are working towards creating useful applications incorporating the technology.

Micromachining

Waveguide technology is a desirable choice for terahertz devices, mainly due to its low loss characteristics.

A waveguide is just a rectangular tube which carries the electromagnetic wave. The conventional way of making waveguide components is precisely controlled CNC metal milling. However, with the increase in the frequency it is more and more challenging to machine the small features and sometimes it is impossible to achieve complicated internal waveguide structures.

Recently, various micromachining techniques have been developed to fabricate such devices with higher precision and possibility at a low cost. Among them is the thick layer SU8 photoresist technology, which affords good dimensional accuracy and at the same time only requires standard ultraviolet photolithography, making it a highly desirable choice for high precision and high-performance applications. More information on this technology is available elsewhere on the website.

We use modern micromachining techniques primarily for the construction of ultra-small passive circuits. We have accurately constructed waveguides for 700 GHz applications, creating a waveguide tube of just 380 by 191 microns. In addition to the SU8 photolithography, work is underway on laser machining and silicon micromachining.

Novel resonator based circuit designs

The microwave industry is dependent upon passive circuits such as filters, multiplexers, antennas and many other components. We work to develop new types of passive circuits primarily based on the coupling of resonators.

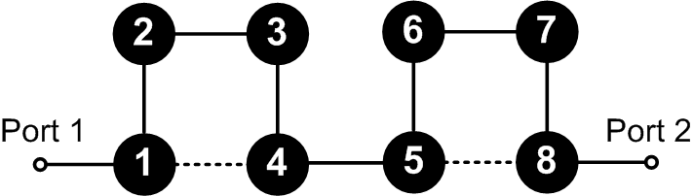

The microwave bandpass filter can be considered as a series of coupled resonators as shown in the figure below. Here there are 8 resonators shown as black dots each coupled together with the straight lines. The input and output are represented by white circles.

A bandpass filter with the black dots representing resonators and the lines representing coupling between the resonators. The dotted line is a coupling, but also known as a cross coupling

A bandpass filter with the black dots representing resonators and the lines representing coupling between the resonators. The dotted line is a coupling, but also known as a cross coupling

Our design method supports the use of any type of resonator, including waveguide, microstrip or dielectric resonators. The type of resonator can be chosen to suit the application.

The same principles can also be applied to non-electromagnetic resonators, for example, acoustic, mechanical or even water waves. We have developed design principles for bandpass filters with simple responses over many years and the technology is mature. However, over the last few years we have pioneered the development of new structures based on the principle of coupled resonators. These include multiband filters; multiport circuits; orthomode transducers; antennas and non-linear circuit with mixers; multipliers; and amplifiers.

3D printing

3D printing or additive manufacturing is now common place and simple printers can be purchased for several hundred pounds. We focus on how 3D printed components can be used in microwave circuits to make new, novel microwave circuits. We collaborate on the manufacturing process and post printing processes to improve the microwave performance. We have demonstrated high performance devices from 0.5 GHz to above 100 GHz.